The disturbing phenomenon of little girls reaching early menarche — some younger than 8 years — set me out on a search for organic milk in 2012-13. I didn’t want my little girl to grow up on growth hormones passed on to humans primarily from cows and buffaloes (and other meat products if you are a non-vegetarian). I didn’t want her to reside in a body ravaged by the hormonal upheavals that her tender age could hardly come to terms with.

Equally disturbing was the unspeakable violence — physical, physiological and psychological — that these innocent animals suffer when injected with hormones to increase milk yield and muzzled calves tethered to a pole while their mothers are milked amid inflicting pain on them in many ways. No matter from which angle we look these two issues, they are our civilisation’s colossal moral failures.

Disclaimer: Please note: 1. I buy Akshayakalpa dairy products. 2. Recently, the firm chose Endlessly Green’s Eartha composters to process their kitchen waste.

It was around this time I came to know about Akshayakalpa products through an organic store. I did background checks. When I called its founder Dr GNS Reddy to discuss how truly organic his company was, he immediately arranged for a tour of his bold enterprise. For some reason, I had to call it off. Had I made it, I would have had the chance to meet the pioneer whose vision — a farmer-entrepreneur initiative — was to make farmers self-reliant through decent income, among others. Nevertheless, I started buying Akshayakalpa dairy products. Although my family’s dairy consumption has reduced drastically since 2017, whatever little we consume comes from here.

Recently, I got a chance to visit Akshayakalpa located at Tiptur in Tumkur district for the inauguration of their massive dairy processing unit which is a harmonious blend of cutting-edge technology and time-tested traditional practices. Co-founder and CEO Shashi Kumar’s decision to go for Eartha composters to process the kitchen waste generated by the staff canteen was another reason. “For the 9th consecutive month, we have paid more than Rs 1 lakh to our farmers as income,” he told the gathering while assuring the chief guest and his uncle, Mr Reddy, that his vision was being realised despite seemingly insurmountable challenges.

Over the years, Akshayakalpa faced possible shutdown six times, but managed to sail through the choppy waters with grit and determination. But what I found most heartening as a visitor to the campus was the fact that none of those hurdles overshadowed the firm’s commitment to a holistic template to establish a self-sustaining entity by managing its water, waste and energy sensibly by investing huge sums that most other private entities would look at as a meaningless expenditure.

One compelling reason for that is Shashi Kumar’s belief in turning this little 24-acre spot on Planet Earth into an ecosystem of influences and inspirations. A revitalising exploration of possibilities for anyone who decides to enter an unknown territory just like its pioneer did decades ago. Coursing through him is the pulse-beat of a long-time conviction that what comes from the earth must go back to it.

As you read on, you will know how Akshayakalpa constantly works on feeding the life forces that keep its campus thriving and humming with tunes in harmony with Nature—be it all the native trees that have brought a once-bare land back to life, or that little organic vegetable patch that feeds the staff, or those birds, bees and butterflies that join the organic feast.

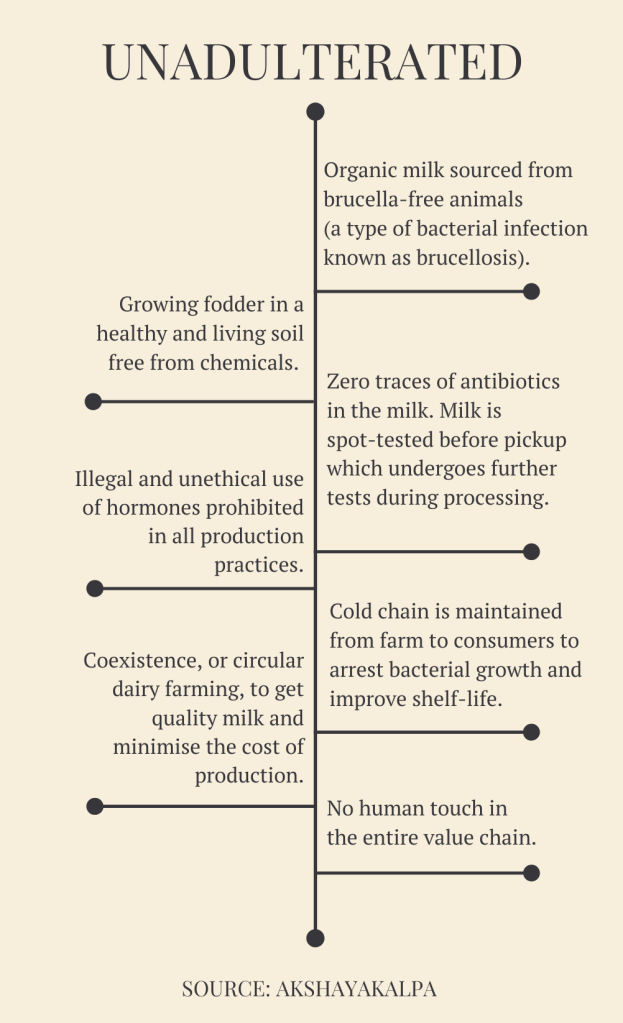

About all things white and organic

Manager for Talent Engagement and Development Manjappa Honnappanavar, who has done MSc in Forestry and has his own gentle and sure-footed ways of engaging his environmental sensibilities, took me on a farm tour. The untethered, freely roaming cows in clean surroundings with enough fresh and processed fodder, and the troughs filled with crystal-clear water, were the first to catch my attention. The animals looked well-fed, full of life and well cared for. Their eyes had a spark and their routine seemed stress-free.

Manjappa briefly explained the fermentation process of various organic produce grown in their farm which are then fortified with macro- and micro-nutrient-rich organic additives to prepare the fodder. I saw four heaps of processed fodder being mixed by the workers. Manjappa said there was no one-size-fits-all fodder as each type was meant for animals at different stages: newborn, young, mature, pregnant cows, etc.

The milking machines which ensure not just hygiene but also a relatively pain-free experience as they mimic sucking action by the calf (as manual milking by humans can cause pain and severe discomfort to the animals), the cold storage systems, processing and packaging methods carried out in a scientific manner.

The four huge silos currently impound 42,000 litres of milk sourced from satellite organic farms run by individual farmers under the strict guidance of the Akshayakalpa team. The milk undergoes spot testing for antibiotics and gets transferred into a cold storage immediately. Once it reaches the farm, further processing happens. “Unlike other brands, milk from our farm reaches the customer in one or one-and-a-half days, maximum,” says Manjappa.

Is that all about Akshayakalpa, a leading organic dairy brand? “It’s just the entry point,” Shashi Kumar says. Their engagement with the farmers collectively farming in 500+ farms spread over 2,000 acres of land and their economic upliftment gets him talking no end. “Several farmers who were deep in debt are now earning a sum never thought of.”

Water

Right next to the dairy processing unit is the effluent treatment plant (ETP), which called for a Rs 4-crore investment. The waste from the processing unit, cattle dung and urine get collected in different tanks and get aerated and treated consistently. This plant cannot stop even for a minute. Hence, huge diesel generators act as a power back-up. Manjappa showed me how the murky water undergoes transition and finally bursts out of a pipe — all clean and ready to irrigate the entire farm. When I asked if the firm had been able to recover the investment, he said: “We don’t look at it as a revenue-generating operation. We do it to save water to remain self-sustaining, for environmental safety and benefits.”

The emphasis on self-sustainability falls on each aspect like water management which is being done efficiently throughout the campus. Since Covid precautionary measures were underway, I didn’t have a chance to visit their offices but the pedal-operated hand wash basins did not go unnoticed.

Biogas & solar

The management is now focused on solarising all the satellite farms as the remote rural areas face power cuts often which brings their milking machines and pressure-cleaning hoses to a halt affecting their schedule. A pilot solarisation programme, started with two farms which currently generate 5kv power, is now being extended to seven more farms generating 5kv each in the second phase.

Similarly, a biogas plant fed with cattle dung generates 50 kWh of power every day. Once the methane gas is converted to electrical energy, it runs the milking machines, chaff cutters, pressure washers, bulk milk coolers and also pumps water from borewells.

“The dung from the stalling area is mechanically flushed into the digester to avoid the drudgery of dung handling,” says Rajeev Krishnamurthy, Operations Head – Extension.

The gas is also used for cooking, heating water in boilers for cleaning all the milk equipment. The slurry is used for farming purposes to enhance soil fertility.

Solar energy and biogas are an integral and critical investment component of the Akshayakalpa model that play a vital role in reducing carbon footprint, recycling waste and mitigating the power shortage woes.

“We intend to make it a zero-discharge and net water-neutral facility in the next five years,” says Shashi Kumar.

Waste

The next heart-warming plus point was their zero-waste campus. Visibly free from single-use non-biodegradable materials, barring the essential plastic used for packaging their products. Right at the entrance and at various strategic locations inside, four colour-coded, labeled dustbins were sitting pretty. During the inauguration, barring the invitees, all the staff members brought their own plates and tumblers to the event, washed them at the temporarily erected pedal-operated wash basins. Segregation of food waste was carried out flawlessly. Water and hot beverage dispensers were installed at strategic points. The guests washed their plates and left them in a trolley which was then taken for the second round of washing by the staff.

During my second visit to train the staff in composting, I had a chance to eat lunch at the canteen. Barring grains and a few other items, most of the fruits and vegetables get sourced from their own organic patch. On that day’s menu were the typical tasty traditional food items like ragi mudde, bassaaru, etc., topped off with a dessert made of banana and jaggery. The staff sticks to the firm’s philosophy of helping themselves with only as much as they can eat and drink to avoid wasting food, beverages and water. Even after serving 300+ meals, the canteen had generated less than half a bucket of leftovers that day.

While all the farm rejects get composted in the traditional heap method using cow dung, the kitchen waste from the canteen called for composters (as part of a statutory requirement). The operation has begun now and the first batch of compost is awaited.

“Akshayakalpa will continue to work to make farming a vocation of choice for young people, and make conscious efforts to safeguard the environment we all live in and ensure that the consumers get substantial value for the produce they buy form us,” adds Shashi Kumar.

Reality is a culmination of all the good intentions we once decided to work on. In other words, when there’s good intent, positive change can’t be far away. Akshayakalpa, in my opinion, is already an end-to-end organic template worth emulating. All it needs is a few stitches here and there to complete the beautiful multi-coloured tapestry its pioneer started weaving years ago.